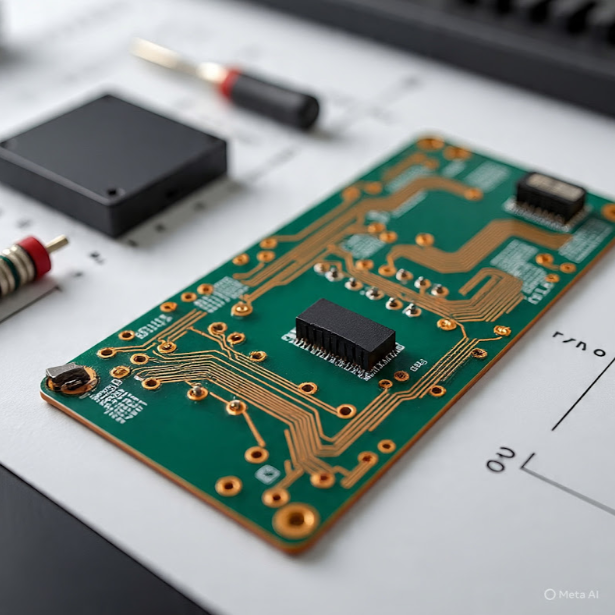

PCB Prototype: Quick-Turn, Low-Volume Prototype Manufacturing Services

In today’s fast-paced electronics industry, speed and precision are everything. As someone who has worked with multiple hardware projects, I can confidently say that having a reliable PCB prototype manufacturer can make or break the success of your product. Whether you are a startup bringing a new device to market or an established company testing innovative designs, finding a quick-turn PCB prototype service that meets your requirements is crucial.

Prototyping is not just about testing a design; it’s about iterating quickly, spotting flaws early, and reducing production risks. This is where low-volume PCB prototype services shine—they allow for flexibility without breaking the bank. In this article, we’ll explore why prototype PCB manufacturer services are vital, what makes a Quick-turn PCB Prototype Service stand out, and how you can leverage Low Volume PCB Prototype Manufacturing to accelerate your product development.

Why PCB Prototyping is Essential

Creating a printed circuit board (PCB) prototype is more than just producing a small batch of boards. It is an essential step in verifying the functionality, performance, and manufacturability of your electronic design. From my personal experience, skipping or rushing this phase can lead to costly mistakes in mass production.

A prototype PCB manufacturer ensures that your design transitions smoothly from concept to physical board. They help detect errors in circuit layout, component placement, and electrical performance before you commit to large-scale production. Moreover, working with a quick-turn PCB prototype service can dramatically reduce your development cycle. Instead of waiting weeks, you can receive functional prototypes within days, allowing for rapid testing and design iterations.

Features of Quick-Turn PCB Prototype Services

When looking for a Quick-turn PCB Prototype Service, several features make a manufacturer stand out:

1. Fast Turnaround Time

The most obvious advantage is speed. Quick-turn services often deliver prototypes within 24 to 72 hours, depending on complexity. From my own projects, I’ve seen how a rapid prototype can accelerate the entire design cycle, allowing engineers to move from concept to testing without delays.

2. High Precision and Quality

Even though the turnaround is fast, quality cannot be compromised. A reliable prototype PCB manufacturer ensures high precision in layer alignment, trace width, and solder mask application. This is critical because even minor errors in a prototype can result in misleading test results.

3. Flexible Volume Options

Not all projects require hundreds of boards. This is where low-volume PCB prototype services are invaluable. They allow you to order small quantities, which is perfect for testing, validation, and pilot runs. I’ve personally opted for low-volume runs multiple times, and it has saved both money and time while still achieving accurate testing results.

See also: Transforming Modern Manufacturing with Advanced Casting Techniques

Advantages of Low-Volume PCB Prototypes

Low-volume production is more than just a cost-saving strategy; it provides a range of benefits that are particularly relevant to startups and small teams:

Reduced Costs

Producing a few prototype boards rather than a full batch is significantly cheaper. This allows designers to test multiple iterations without incurring prohibitive costs.

Flexibility in Design Changes

With low volume runs, it’s easier to make adjustments. If you discover that a trace needs rerouting or a component requires repositioning, a small batch can be re-manufactured quickly.

Accelerated Testing

Low volume prototypes enable engineers to conduct real-world testing without committing to large-scale manufacturing. From my experience, having tangible prototypes on hand during early testing phases can reveal issues that simulation software alone cannot detect.

Choosing the Right Prototype PCB Manufacturer

Selecting the right prototype PCB manufacturer is key to a successful project. Here are some points to consider:

Experience and Expertise

A manufacturer with experience handling quick-turn and low-volume projects will understand the nuances of PCB prototyping. They can offer guidance on materials, design optimization, and potential pitfalls.

Advanced Manufacturing Capabilities

Ensure that your chosen Quick-turn PCB Prototype Service has modern equipment capable of handling high-density, multilayer boards. Advanced facilities reduce the risk of errors and increase reliability.

Customer Support and Communication

Prototyping often involves multiple revisions and questions. A manufacturer that communicates effectively and provides transparent updates will save you considerable stress.

My Personal Take on PCB Prototyping Services

From my perspective, working with a professional PCB manufacturer is not just about ordering a board; it’s about building a partnership. I recall a project where our initial design failed functional testing. Thanks to our quick-turn PCB prototype provider, we were able to iterate within three days instead of three weeks. This flexibility not only saved the project but also strengthened our design confidence.

Another advantage I have observed is how low-volume PCB prototype services reduce the fear of experimenting. When you know you can produce small batches without high costs, you are more willing to test innovative ideas. Innovation thrives when risk is minimized, and in my opinion, prototyping services play a crucial yet often overlooked role in this process.

The Future of Quick-Turn and Low-Volume PCB Manufacturing

The electronics industry is evolving rapidly. With IoT devices, wearable tech, and smart gadgets gaining momentum, the demand for Quick-turn PCB Prototype Service and Low Volume PCB Prototype Manufacturing will continue to rise. Manufacturers are now incorporating automation, rapid testing, and advanced materials to support faster iterations and more complex designs.

For engineers and designers, this means that waiting weeks for a prototype is becoming obsolete. Instead, a reliable prototype PCB manufacturer allows for agile development cycles, faster time-to-market, and improved product quality. Personally, I see this trend as a game-changer for startups and innovators alike.

Conclusion

In conclusion, a dependable PCB prototype manufacturer is essential for anyone serious about electronics development. Quick-turn services ensure that your design reaches testing quickly, while low-volume production provides flexibility, cost savings, and the freedom to iterate.